- 0086 189 2383 9762

- [email protected]

- 268 Shu'an Rd, Dongguan, Guangdong Province, China, 523850

- Home

- CNC Machining

- Pages

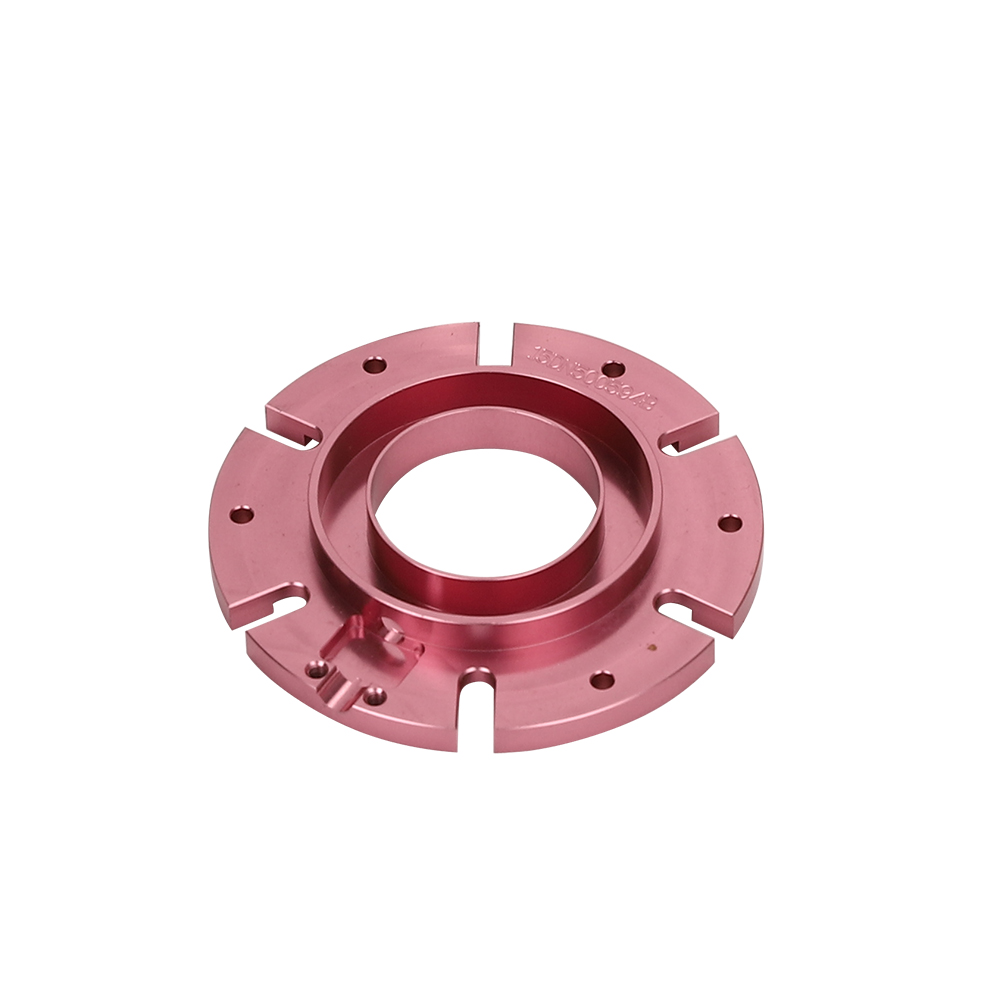

- Wholesale Price Precision CNC Machining Brass Parts

Wholesale Price Precision CNC Machining Brass Parts

Wholesale Price Precision CNC Machining Brass Parts

Brass, a versatile copper alloy, stands out for its remarkable properties, making it a preferred choice for CNC machining applications. Understanding its composition, grades, finishes, and machining tips can help optimize the production of high-quality brass parts. Here’s a comprehensive guide to wholesale price precision CNC machining brass parts:

Understanding Brass Composition and Attributes

Brass encompasses a range of copper-zinc alloys, varying in zinc content and including additional elements like lead, aluminum, and iron. Its copper base grants it thermal and electrical conductivity, along with good wear resistance. The inclusion of lead enhances machinability, making brass the most machinable of all copper alloys.

Applications of Brass in CNC Machining

Brass offers mechanical strength, lower friction, and improved corrosion and wear resistance compared to basic copper. These qualities make it ideal for mechanical applications, particularly in environments where corrosion resistance is crucial, such as the marine industry.

Common Brass Grades Used in CNC Machining

Two common brass grades used in CNC machining are Cartridge Brass (Copper C260) and Free-Cutting Brass (Copper C360). Cartridge Brass finds application in ammunition cartridges, rivets, hinges, and radiator cores, while Free-Cutting Brass is preferred for gears, screw machine parts, and valve components due to its high machinability.

Finishes and Post-Processing Options

Brass parts can be left uncoated due to their inherent conductivity, corrosion resistance, and low friction coefficient. However, surface finishes like hand polishing, buffing, or honing can enhance their aesthetic appeal. As machined surfaces of brass parts often have attractive finishes, leaving them as machined is a viable option.

Cost-Saving Design Tips

Optimizing the use of brass involves considering design for manufacturing (DFM) principles and selecting the right grade based on the application. Minimizing the number of machine setups and choosing appropriate brass grades can help reduce machining costs.

Benefits of Custom Machined Brass CNC Parts

Brass offers several advantages for CNC machining applications, including:

- Cost savings compared to denser metals.

- Antibacterial properties.

- High workpiece-to-tool compatibility.

- Excellent recyclability.

- Great electrical conductivity.

Applications of Brass CNC Machined Parts

Brass CNC machined parts find applications in various industries, including automotive, filtration, plumbing, and more. Examples of brass components produced through CNC machining include pipe and flare fittings, bearings, compression orifices, bushings, and nuts and bolts.

Wholesale price precision CNC machining brass parts offer a cost-effective solution for producing high-quality components with superior mechanical properties and corrosion resistance. Understanding brass composition, grades, finishes, and machining tips is essential for optimizing the production process and achieving excellent results in various applications.

CNC-Machining

Find various CNC-Machining products from our factory, and get the free OEM/ODM services.