- 0086 189 2383 9762

- [email protected]

- 268 Shu'an Rd, Dongguan, Guangdong Province, China, 523850

- Home

- CNC Machining

- Pages

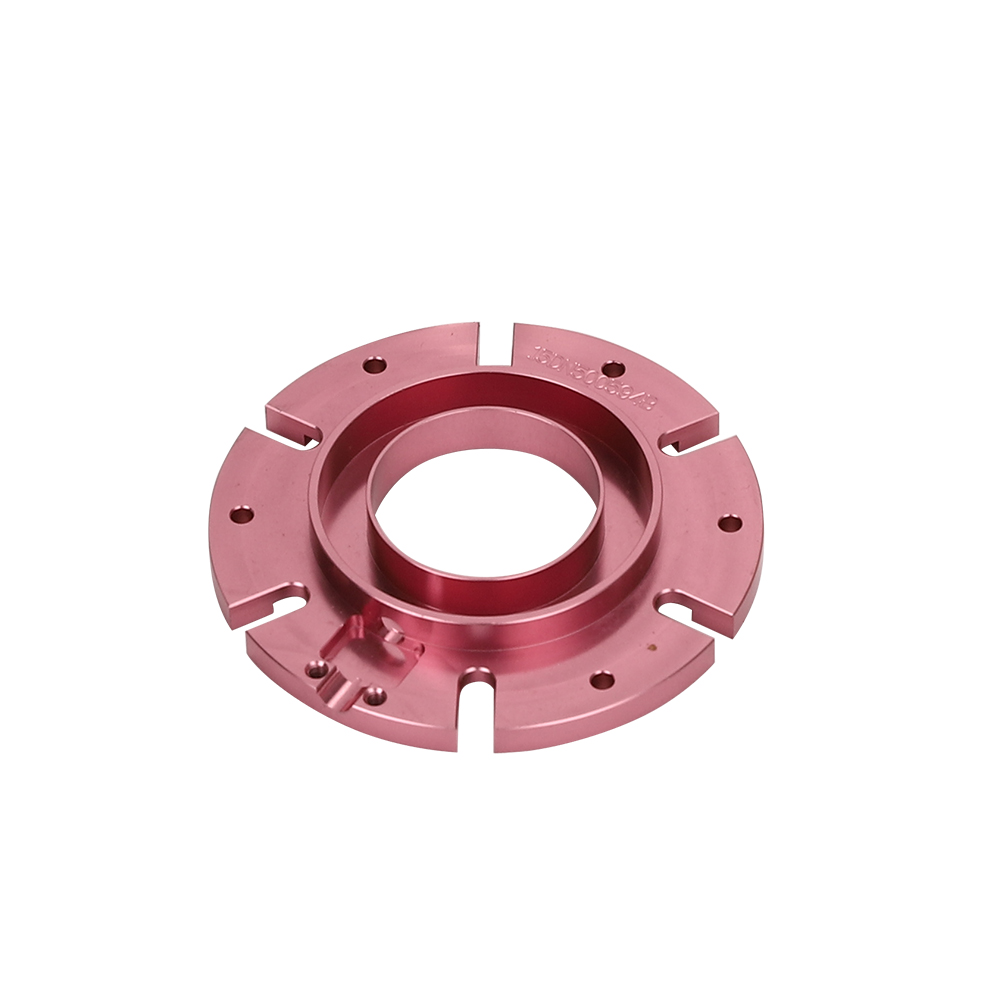

- Precision OEM Custom Brass Parts CNC Turning Parts Services

Precision OEM Custom Brass Parts CNC Turning Parts Services

Choosing Brass Alloys for Precision OEM Custom Brass Parts

Brass, derived from a blend of copper and zinc, embodies a captivating golden hue, rendering it a favored material for crafting ornamental items. Renowned for its non-magnetic properties, ease of casting, and minimal need for surface finishing, brass boasts a low coefficient of friction, a modest melting point, exceptional malleability, and robust corrosion resistance.

In the realm of precision OEM Custom Brass Parts, brass alloys present a wealth of advantages across diverse manufacturing processes, encompassing castings, forgings, and extrusions. From its economical nature to its remarkable thermal conductivity, brass emerges as a versatile material option, catering to a multitude of applications with efficacy and reliability.

Cost-Effective Precision: Maximizing Efficiency

Custom Brass Parts alloys require less machining compared to other materials, reducing the need for expensive secondary operations. With multiple details integrated into single forgings or castings, manufacturers can achieve significant cost savings without compromising quality.

Swift Turnaround: Meeting Tight Deadlines

Quick turnaround times are essential in today’s fast-paced manufacturing environment. Brass fabrication processes, such as casting and extrusion, enable rapid production, ensuring timely delivery of precision OEM custom parts to meet project deadlines.

Superior Properties: Strength and Versatility

Custom Brass Parts boasts excellent thermal and electrical conductivity, making it suitable for a wide range of applications. Its good machinability, coupled with the ability to support complex features and critical geometric tolerances, ensures precise outcomes for intricate part designs.

Exploring Brass Alloys for Extrusions and Castings

Different Custom Brass Parts alloys cater to specific requirements, offering unique combinations of properties suited to diverse applications. Let’s delve into some of the best brass alloys for extrusions, castings, and forging:

Aluminum Brass & Bronzes: Ideal for high-strength and corrosion-resistant applications, these alloys excel in brass castings, providing durability and reliability.

Nickel Silver: Known for their decorative appeal and industrial strength, nickel silver brass alloys offer versatility in both extrusions and castings, combining aesthetics with functionality.

Corrosion-Resistant Brass: With excellent resistance to marine environments, corrosion-resistant brass alloys are suitable for applications requiring durability and longevity.

Dezincification-Resistant Brass: Specialized alloys resistant to dezincification find utility in aggressive water environments, ensuring reliability in challenging conditions.

Lead-Free Brass Alloys: Complying with safety regulations, lead-free brass alloys offer peace of mind for drinking water applications, prioritizing health and environmental sustainability.

High Tensile Brasses: Combining strength with wear and corrosion resistance, high tensile brass alloys are ideal for demanding applications such as fasteners and valve components.

Architectural Brass/Bronze Alloys: These alloys lend themselves to architectural designs, offering durability and aesthetic appeal for various structural and decorative elements.

Cold Forming Brass Alloys: Known for their ductility, cold forming brass alloys are ideal for applications requiring precise cold heading and riveting.

Hot Forging Brass: Retaining dimensional accuracy and minimal porosity, hot forging brass alloys are well-suited for complex forging parts requiring intricate shapes and high flow.

Gilding Metal: Widely used in decorative applications such as jewelry making, gilding metal offers corrosion resistance and an attractive bronze color, perfect for ornamental designs.

Conclusion: Precision Craftsmanship with Brass Alloys

Brass alloys continue to be the material of choice for precision OEM custom parts, offering a blend of cost-effectiveness, versatility, and superior properties. From intricate extrusions to ornamental castings, brass caters to a diverse range of applications, delivering reliable performance and aesthetic appeal. By selecting the right brass alloy for specific requirements, manufacturers ensure optimal outcomes, meeting the demands of modern industries with precision craftsmanship and innovation.

CNC-Machining

Find various CNC-Machining products from our factory, and get the free OEM/ODM services.