- 0086 189 2383 9762

- [email protected]

- 268 Shu'an Rd, Dongguan, Guangdong Province, China, 523850

- Home

- CNC Machining

- Pages

- Most Efficient Custom CNC Aluminum Parts CNC Turned Parts

Most Efficient Custom CNC Aluminum Parts CNC Turned Parts

Most Efficient Custom CNC Aluminum Parts and CNC Turned Parts

Aluminum, with its lightweight and versatile nature, has revolutionized various industries, from transportation to construction. Its properties make it an ideal material for CNC machining, offering durability, malleability, and excellent machining characteristics. Let’s delve into the efficiency and versatility of custom CNC aluminum parts and CNC turned parts.

Advantages of Aluminum in Various Industries

Transportation: Aluminum’s combination of lightness and strength makes it indispensable in automobiles, airplanes, railways, and marine applications. Its use in fuel-efficient engines contributes to reduced fuel consumption and emissions.

Construction: Aluminum’s corrosion resistance and low weight make it ideal for constructing buildings, particularly in earthquake-prone zones. Its reflective properties also find applications in lighting fixtures.

Vehicles: Aluminum structures in automobiles absorb a high proportion of shocks during accidents, enhancing safety.

Air Travel: Strong aluminum alloys endure the extreme pressures of high-altitude flying. Its lightness contributes to fuel efficiency and increased payload in aircraft.

Electrical Transmission: Aluminum’s conductivity makes it suitable for electrical transmission lines, light bulbs, and telephone wires.

CNC Machined Aluminum: A Versatile Solution

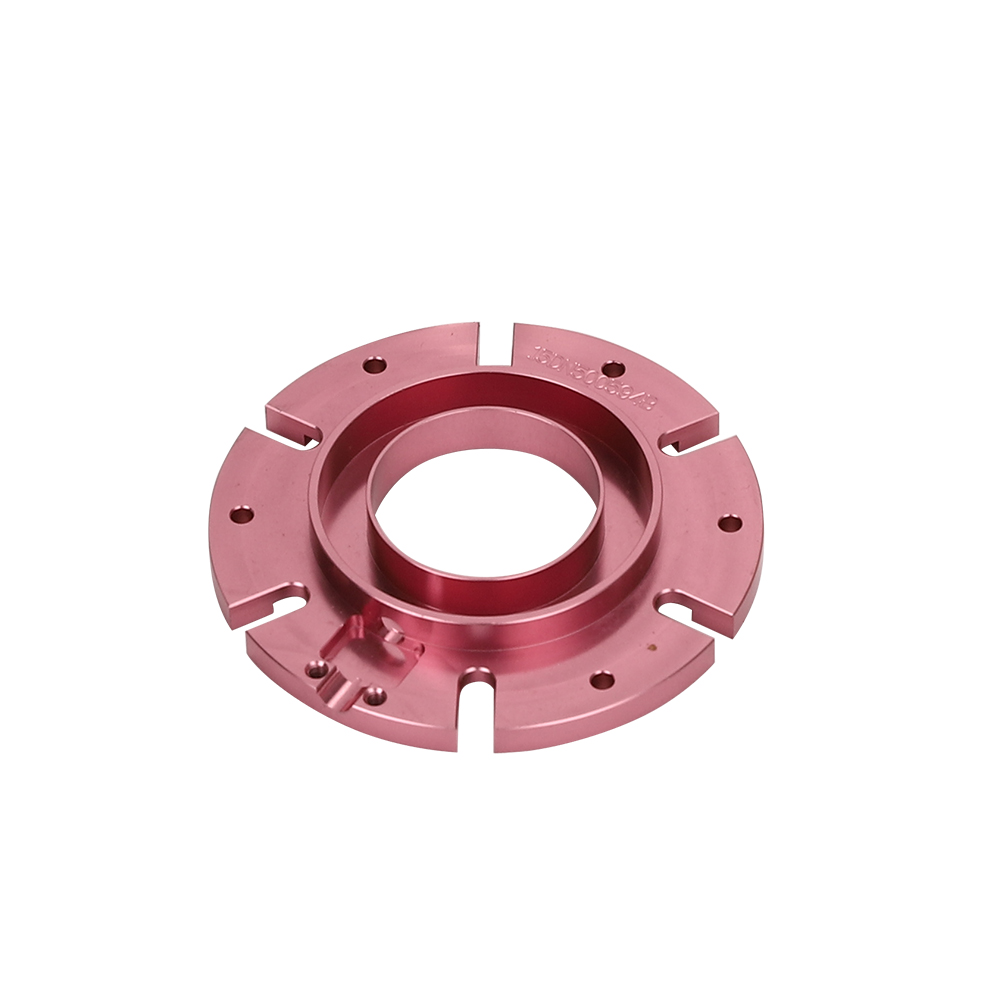

Aluminum’s machinability makes it a prime choice for CNC machining. CNC machining starts with a raw aluminum piece, which is meticulously shaped using Computerized Numerical Control (CNC) machines. These machines, guided by Computer-Aided Design (CAD) software, can craft intricate three-dimensional objects with precision.

Aluminum Machine Shops: Our Extensive Network

With over 240 aluminum machine shops in our network, we boast immense capacity and diverse machinery capabilities. Our machine shops can produce custom aluminum parts using CNC turning machines and 3- & 5-axis CNC milling machines. We offer a wide range of aluminum types, including popular alloys like Aluminum 6061-T6, Aluminum 7075-T6, and more.

Aluminum Machining Services: Tailored Solutions

Our comprehensive aluminum CNC machining service caters to various needs. Whether your application requires high strength, corrosion resistance, heat tolerance, low weight, or electrical conductivity, we’ve got you covered. We work with different CNC mills and turning centers to produce simple to complex parts with tight tolerances. Additionally, we provide up to 13 post-processing and surface finishing options, including anodizing, powder coating, and electroless nickel plating.

Challenges and Considerations for Aluminum CNC Machining

Choosing the right aluminum alloy is crucial for optimizing technical characteristics. Common types like Aluminum 6061 and Aluminum 7075 offer distinct properties suitable for different applications. Our engineers can provide expert guidance in selecting the appropriate alloy for your project, ensuring optimal performance and durability.

Custom CNC aluminum parts and CNC turned parts offer unparalleled efficiency and versatility across various industries. With our extensive network of machine shops, advanced CNC machining capabilities, and knowledgeable engineers, we deliver tailored solutions to meet your specific requirements. Whether you’re in transportation, construction, or any other industry, aluminum CNC machining offers a reliable solution for your manufacturing needs.

CNC-Machining

Find various CNC-Machining products from our factory, and get the free OEM/ODM services.