- 0086 189 2383 9762

- [email protected]

- 268 Shu'an Rd, Dongguan, Guangdong Province, China, 523850

- Home

- CNC Machining

- Pages

- High Custom Plastic CNC Machining Components Machined Parts

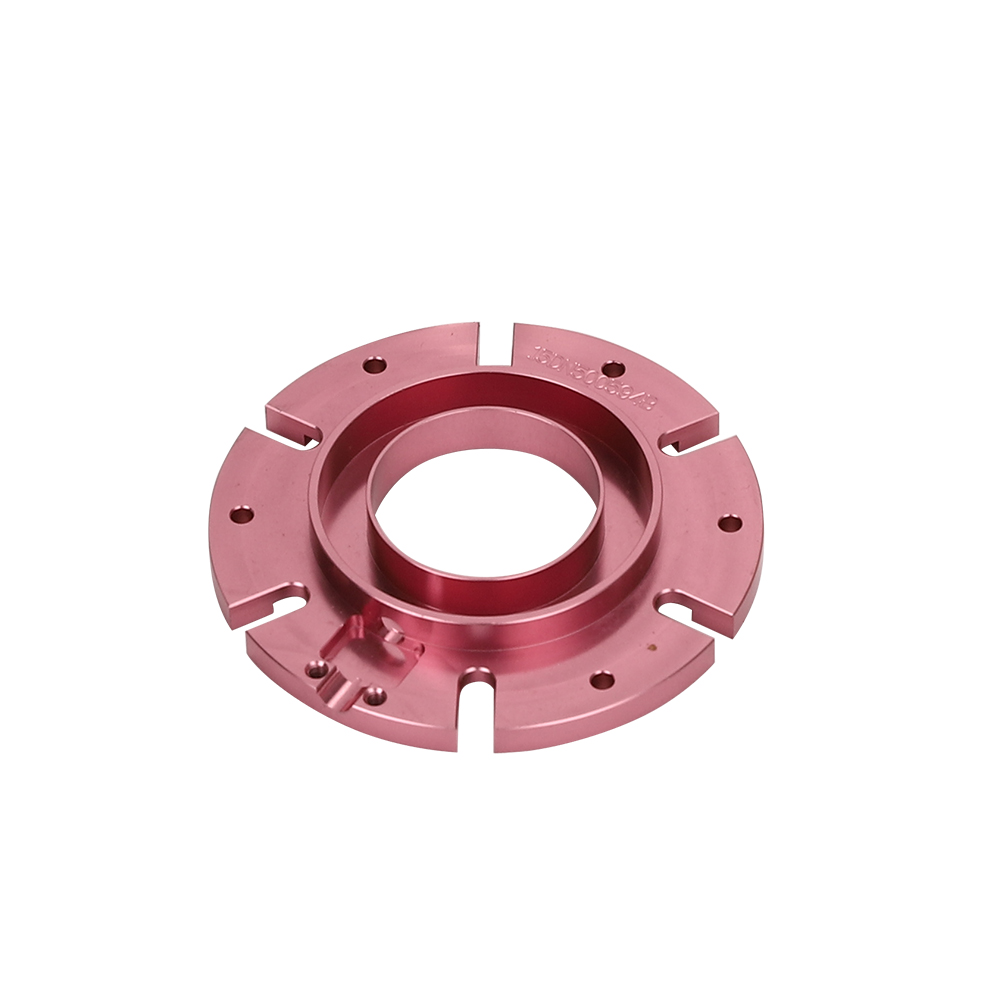

High Custom Plastic CNC Machining Components Machined Parts

Plastic CNC Machining: Versatile Solutions for Diverse Industries

The realm of CNC machining encompasses a wide array of plastics, serving various industries with bespoke solutions. Whether for prototyping or custom parts production, plastic CNC machining offers flexibility and precision tailored to specific applications.

Understanding Plastic Selection for CNC Machining

Selecting the appropriate plastic for CNC machining involves careful consideration of multiple factors. From temperature resistance to mechanical properties, each characteristic influences the suitability of the plastic for the intended purpose. Factors such as corrosion resistance, workability, pricing, weight, and aesthetics all contribute to the selection process.

Unraveling Plastic CNC Machining

Plastic CNC machining employs a subtractive manufacturing approach, utilizing cutting tools guided by digital design files to shape solid blocks of plastic material. This method ensures precise, uniform, and high-quality parts with tight tolerances, meeting the stringent demands of modern manufacturing.

Delving into Plastic Turning and Milling

Plastic turning and milling are integral processes in CNC machining, each offering unique advantages. While turning involves rotating the workpiece against a stationary cutting tool to shape it, milling employs rotating spindles to remove material from plastic workpieces mounted on a table, enabling multi-axis machining for complex geometries.

Advantages of CNC Plastic Machining

Plastic CNC machining presents numerous benefits over alternative manufacturing methods:

- Mold-Free Production: Unlike injection molding, CNC machining eliminates the need for molds, facilitating cost-effective production of prototypes and short-run batches.

- Tighter Tolerances: CNC machining ensures superior precision and accuracy, making it suitable for applications requiring high-precision measurements.

- Material Versatility: With a wide range of engineering-grade plastics available, CNC machining offers versatility in material selection, catering to diverse application requirements.

Choosing Between CNC Machining and 3D Printing

The decision between CNC machining and 3D printing hinges on factors such as part size, material compatibility, accuracy requirements, and intricacy of details. While 3D printing excels in rapid prototyping and small-scale production, CNC machining offers superior accuracy, material versatility, and efficiency for larger parts with intricate details.

Applications of CNC Machined Plastic Parts

CNC-machined plastic parts find application across various industries:

- Medical Devices: Precision plastic components for surgical tools, medical devices, and dispensers.

- Food and Beverage Industry: Valves, nozzles, and seals for food processing and packaging machinery.

- Semiconductor Industry: High-performance parts with tight tolerances for semiconductor manufacturing.

- Automotive and Aerospace: Critical components meeting strict regulations and requirements for aerospace and automotive applications.

Access Premium Plastic CNC Machining Services

For comprehensive plastic CNC machining solutions, look no further than AT Machining. With state-of-the-art CNC milling and turning capabilities, we deliver high-quality, precision-engineered plastic parts tailored to your specifications. From prototypes to large-volume production runs, we offer competitive pricing and fast lead times, ensuring timely delivery of superior machined components.

CNC-Machining

Find various CNC-Machining products from our factory, and get the free OEM/ODM services.