- 0086 189 2383 9762

- [email protected]

- 268 Shu'an Rd, Dongguan, Guangdong Province, China, 523850

- Home

- CNC Machining

- Pages

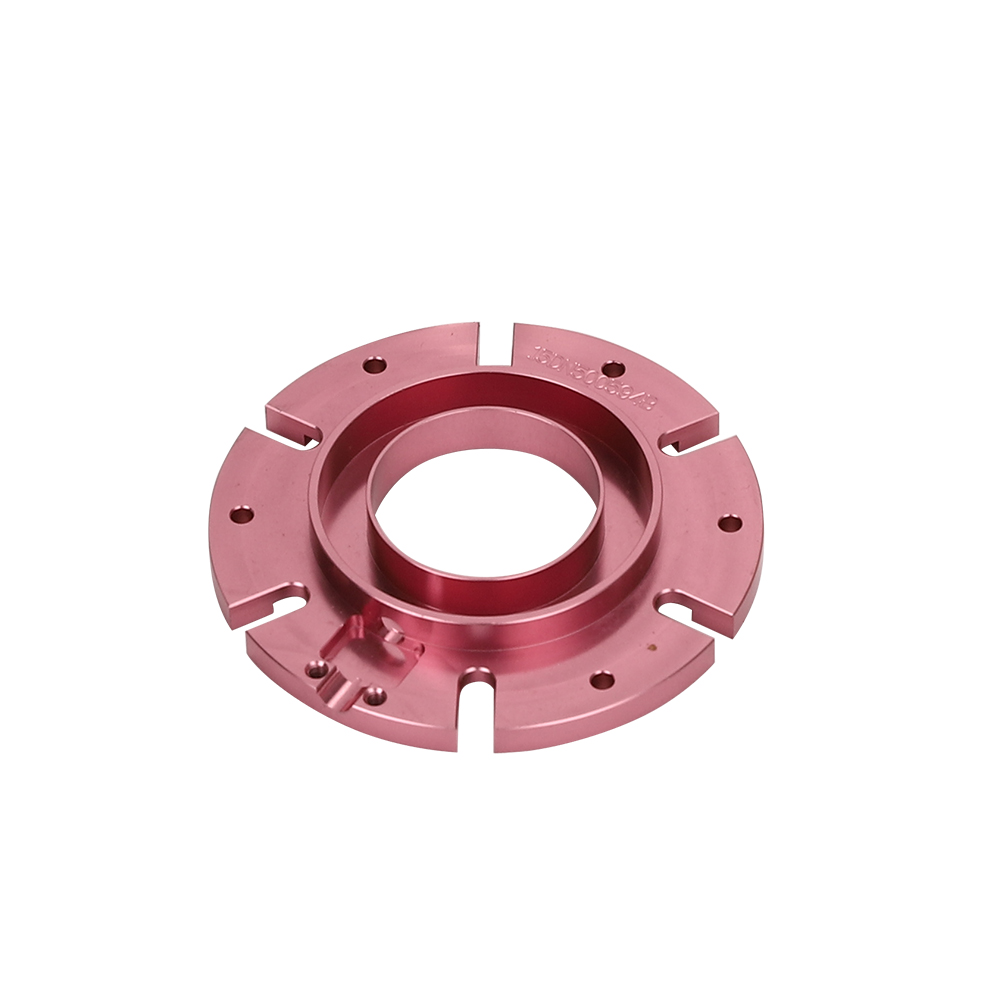

- Good Price CNC Service Milling Machining Aluminum Parts

Good Price CNC Service Milling Machining Aluminum Parts

Unlocking the Potential: Good Price CNC Service Milling Machining Aluminum Parts

Aluminum stands out as an exceptional material for part production, offering a myriad of benefits in various applications. From its lightweight and malleable nature to its corrosion resistance, aluminum proves to be a versatile choice for CNC machining projects. This article explores the advantages of utilizing aluminum parts, common challenges in machining, and key considerations for engineers.

The Versatility of Aluminum

Aluminum boasts a unique combination of properties, including lightness, plasticity, and ease of processing, making it an attractive option for part manufacturing. Its corrosion resistance, coupled with the ability to achieve desired hardness levels, positions aluminum as a cost-effective material choice. Moreover, aluminum parts can be machined three times faster than steel counterparts, leading to reduced production costs and enhanced efficiency.

Advantages Across Industries

Aluminum finds extensive use across various industries due to its exceptional properties:

- Transportation: Aluminum’s lightweight nature contributes to fuel efficiency and emissions reduction in automobiles, airplanes, railways, and marine applications.

- Construction: Corrosion-resistant and cost-effective, aluminum is favored in building construction, particularly in earthquake-prone areas.

- Vehicles: The shock-absorbing properties of aluminum structures enhance safety in automobiles.

- Air Travel: Aluminum’s strength and lightness make it indispensable in aircraft construction, contributing to fuel savings and increased payload capacity.

- Electrical Transmission: Aluminum’s conductivity and flexibility make it ideal for electrical transmission lines, offering efficiency and reliability.

Common Challenges in CNC Machining Aluminum Parts

While aluminum offers numerous advantages, engineers must address specific challenges when designing aluminum parts. Factors such as alloy selection and heat management play crucial roles in ensuring optimal performance and durability. Choosing the right aluminum alloy, such as 6061, 7075, or 2024, requires careful consideration of mechanical properties and application requirements.

Maximizing CNC Machining Capabilities

Modern CNC machines enable the manufacturing of highly complex parts with precision and efficiency. By leveraging advanced machining techniques and equipment, engineers can optimize part designs and streamline production processes. Additionally, CNC turn-milling machines offer enhanced capabilities, allowing for the creation of intricate components at competitive prices.

Ensuring Quality and Precision

At B&K Precision Machining, we specialize in CNC machining aluminum parts with a focus on quality and precision. With access to leading EU suppliers and a team of experienced engineers and machine operators, we ensure that each part meets your specifications and quality standards. Whether you require custom components for transportation, construction, or electrical applications, we’re committed to delivering excellence in CNC machining services.

After reviewing this article, you should recognize the numerous advantageous qualities that aluminum brings to CNC machining. Yet, selecting the right manufacturing partner to oversee your aluminum CNC machining project is paramount.

Thus, it is prudent to collaborate with a CNC shop equipped with the appropriate machining tools to produce aluminum parts of superior quality and precision. Furthermore, the chosen machining service provider should possess extensive experience in manufacturing aluminum parts and hold all necessary quality certifications to ensure compliance with required standards.

Conversely, it is ill-advised to engage with a CNC machine shop lacking essential quality certifications and advanced CNC machinery needed to achieve precise and accurate results. Similarly, entrusting your custom aluminum parts to a partner lacking experience in handling such projects is not recommended.

For all your aluminum prototype and custom aluminum machining needs, CNC-machining stands ready to assist. As a prominent CNC machining specialist, we boast a team of skilled machinists and engineers dedicated to delivering excellence. Leveraging our expertise in CNC aluminum machining, we provide aluminum parts with tight tolerances and expedited cycle times. Contact us today to receive a quote for your project!

In conclusion, aluminum CNC machining represents a widely embraced manufacturing process, thanks to the exceptional potential offered by aluminum alloys. These alloys have enhanced aluminum’s characteristics and properties, rendering CNC aluminum machining an ideal manufacturing solution.

CNC-Machining

Find various CNC-Machining products from our factory, and get the free OEM/ODM services.