- 0086 189 2383 9762

- [email protected]

- 268 Shu'an Rd, Dongguan, Guangdong Province, China, 523850

- Home

- CNC Machining

- Pages

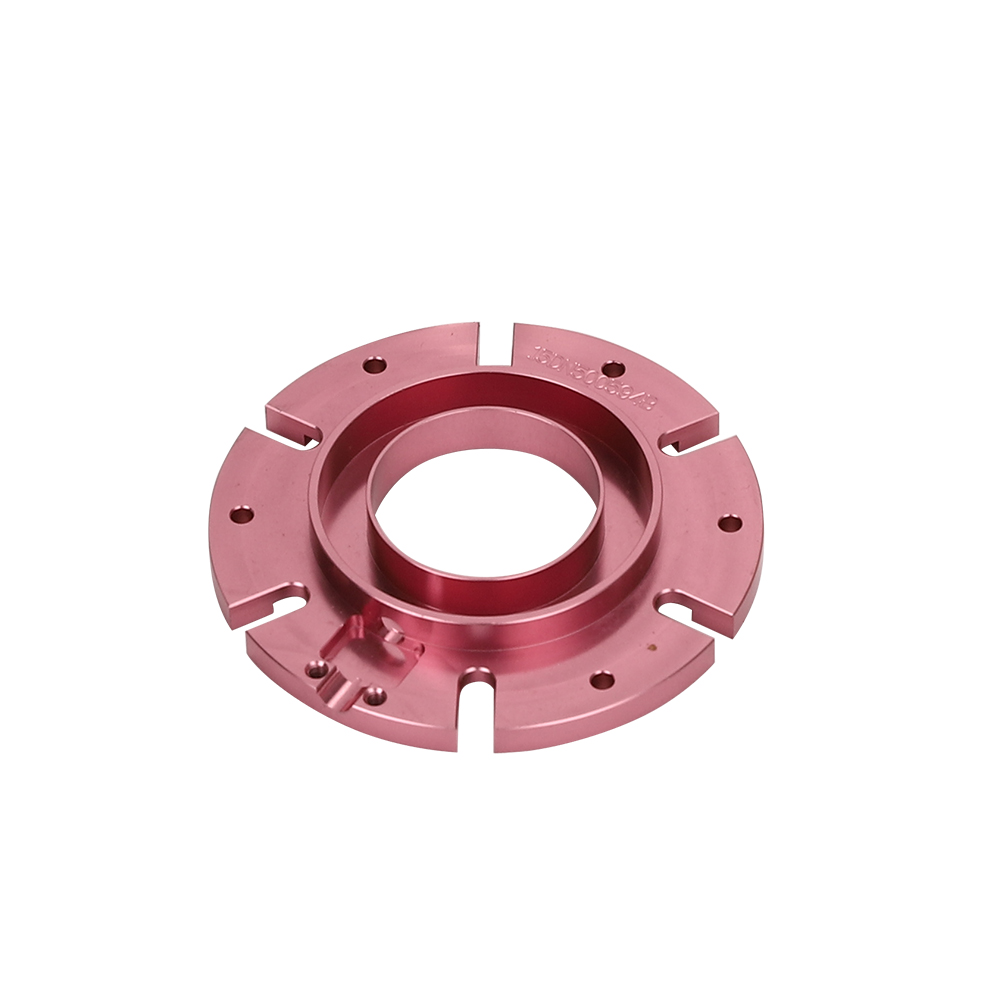

- Customized Precision CNC Machining Stainless Steel Parts

Customized Precision CNC Machining Stainless Steel Parts

Choosing Stainless Steel CNC Machining Parts

Stainless steel, known for its strength, durability, and corrosion resistance, is a preferred alloy for CNC machining. When selecting stainless steel CNC machining parts, considerations such as the part’s application, operating environment, and machinability play crucial roles.

Stainless steel stands out as a versatile material widely employed in CNC machining and CNC turning across diverse industries such as aerospace, automotive, and marine. Renowned for its exceptional corrosion resistance, stainless steel offers a broad spectrum of alloys and grades suitable for various applications. This article delves into the mechanical properties of different types of stainless steel to assist in selecting the optimal grade for your project.

Types of Stainless Steel Alloys

Stainless steel encompasses five main categories distinguished by their alloying elements and material structures:

Austenitic Stainless Steel

Ferritic Stainless Steel

Martensitic Stainless Steel

Precipitation Hardened Steel

Duplex Stainless Steel (austenitic-ferritic)

Austenitic Stainless Steel

Austenitic stainless steel is renowned for its robust corrosion resistance, making it ideal for a wide range of applications, including domestic, industrial, and architectural uses. This category finds extensive use in products such as fasteners, food processing equipment, and industrial gas turbines. Notably, austenitic stainless steel offers excellent machinability and weldability, owing to its predominantly crystalline structure. Popular grades within this category include 304 and 316, containing chromium levels between 16 and 26 percent.

Ferritic Stainless Steel

Comprising around 12% chromium, ferritic stainless steel exhibits distinct magnetic properties attributed to its body-centered cubic grain structure. While it may not match the corrosion resistance of austenitic steel, ferritic steel finds applications in automotive parts and kitchen appliances. Notably, its high resistance to stress corrosion cracking makes it suitable for environments prone to chloride exposure.

Martensitic Stainless Steel

Martensitic stainless steel boasts tough properties, allowing for heat treatment and hardening. Although it typically exhibits reduced chemical resistance compared to austenitic variants, martensitic steel offers cost-effective, air-hardening capabilities. With a minimum chromium content of 10.5%, this steel variant finds usage in various applications, including cutlery, car parts, turbine blades, valves, and surgical instruments.

Selecting the Right Stainless Steel Grade

Choosing the appropriate stainless steel grade for your CNC machining project hinges on several factors, including corrosion resistance, mechanical properties, and intended application. By understanding the characteristics of each stainless steel category, you can make informed decisions to ensure optimal performance and durability in your machined parts.

Versatility of Stainless Steel in CNC Machining

Stainless steel stands out in CNC machining projects due to its excellent machinability, uniformity, workability, and weldability. Its high ductility and formability make it adaptable to various machining requirements, meeting the specifications of diverse projects. The alloy’s outstanding physical properties contribute to its popularity in industrial applications, offering high tensile strength, corrosion resistance, and wear resistance for enhanced product durability.

Physical Properties of Stainless Steel Alloys

Stainless steel alloys, renowned for their high tensile strength, corrosion resistance, and temperature resilience, provide ease of welding, machining, and polishing. These properties make stainless steel a versatile choice for Precision CNC Machining, ensuring that the resulting parts are durable, reliable, and capable of withstanding challenging conditions.

Applications of Stainless Steel Machining

Precision CNC Machining of stainless steel finds application in a range of industries, including medical, robotics, food and beverage, aerospace, and heavy machinery. This versatile material is employed in manufacturing medical instruments, machine parts, gears, components for tractors, heavy construction equipment, and vacuum/pressure vessels. The corrosion and oxidation resistance of stainless steel contribute to its suitability for diverse applications, ensuring a longer product life and lower total cost for machined parts.

Benefits of Stainless Steel 304/304L and 316/316L

Stainless steel grades 304/304L and 316/316L offer numerous benefits, including improved machinability, outstanding uniformity, faster machining speeds, longer tool life, superior part surface quality, corrosion resistance, and a lower total cost for machined parts.

Benefits of Stainless Steel 303

Stainless steel type 303, designed for enhanced machinability, is a non-magnetic austenitic stainless steel with corrosion-resistant properties. Its resistance to oxidation makes it a suitable choice for various Precision CNC Machining applications.

Benefits of Stainless Steel Type 360

Type 360, a precipitation-hardening martensitic stainless steel, provides superior corrosion resistance, high strength in all conditions, and good machinability. These qualities make it an ideal option for demanding Precision CNC Machining requirements.

In conclusion, stainless steel emerges as a highly versatile material for CNC machining, offering a diverse range of alloys tailored to specific requirements across multiple industries. Whether for industrial machinery, automotive components, or precision instruments, the right stainless steel grade can significantly enhance the performance and longevity of your CNC machined parts.

CNC-Machining

Find various CNC-Machining products from our factory, and get the free OEM/ODM services.