- 0086 189 2383 9762

- [email protected]

- 268 Shu'an Rd, Dongguan, Guangdong Province, China, 523850

- Home

- CNC Machining

- Pages

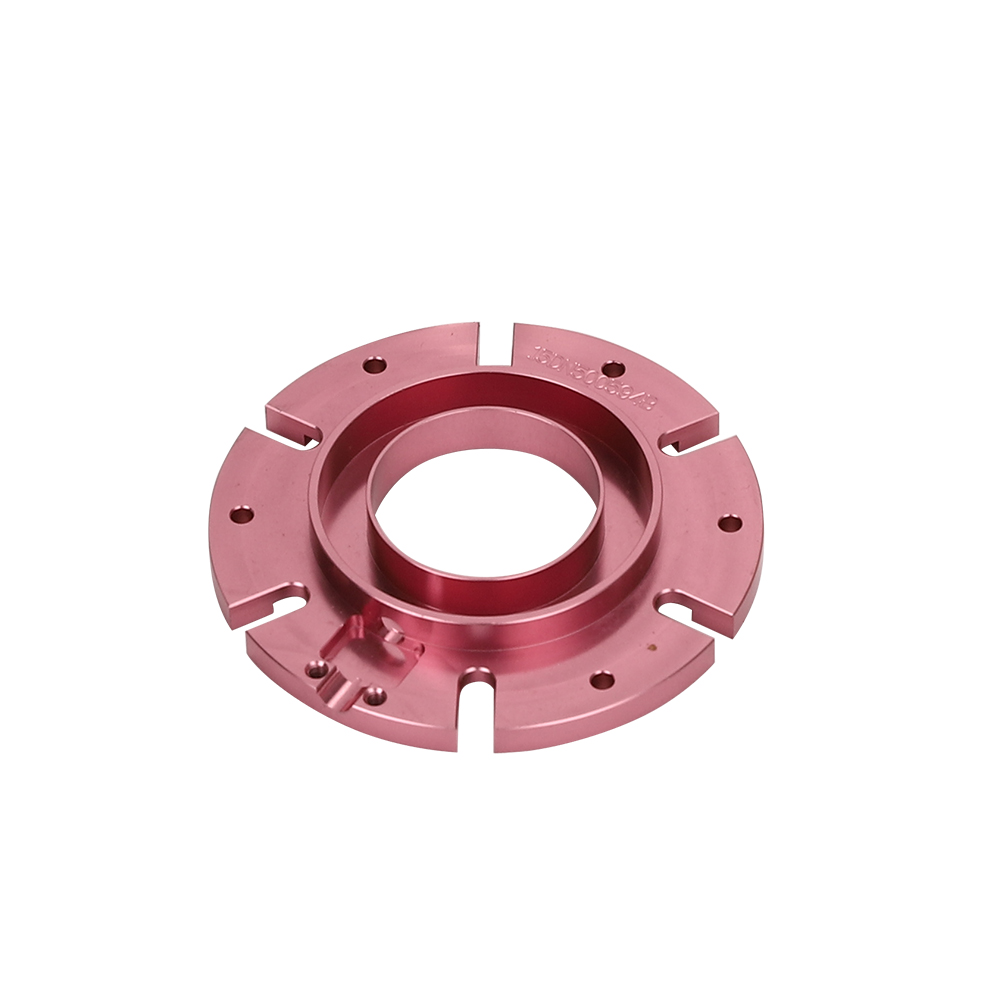

- Custom CNC Plastic Machining Components ABS Machined Parts

Custom CNC Plastic Machining Components ABS Machined Parts

Mastering CNC Plastic Machining: A Guide to Precision

Unlocking the potential of CNC plastic machining requires a deep dive into material selection, machining processes, and surface finishing techniques. Let’s explore the intricacies of this craft and unveil the key factors that contribute to mastering CNC plastic machining.

Selecting the Optimal Plastic Polymers

In the realm of CNC plastic machining, thermoplastics stand out for their post-molding resilience. Here’s a closer look at some top contenders:

Delrin (POM): Revered for its robustness, Delrin thrives in high-stress environments. However, it’s imperative to heed its temperature limitations.

Nylon (Polyamide): Nylon’s remarkable thermal and mechanical properties make it a machining favorite, offering tight tolerances and dimensional stability.

Acrylic: Lightweight yet sturdy, acrylic boasts excellent tensile strength and wear resistance. Achieving flawless CNC cuts requires precision tools tailored to its characteristics.

PTFE (Teflon): Recognized for its resilience against various elements, PTFE poses challenges in achieving tight tolerances due to its friction and stress properties.

PEEK: With a high melting point and superior mechanical traits, PEEK excels in demanding applications. Careful machining strategies mitigate heat-induced stresses for optimal results.

UHMW: Despite its instability, UHMW’s exceptional properties, including high tensile strength, make it a sought-after material for precision machining.

Machining Plastic: Processes Demystified

CNC plastic machining encompasses diverse processes tailored to material nuances and project specifications:

CNC Turning: Suited for cylindrical shapes, CNC turning involves rotating plastic on a lathe while precision tools sculpt the desired form.

CNC Milling: By employing rotating tools on a stationary material, CNC milling achieves intricate shaping of flat and irregular components with precision.

CNC Drilling: This method bore holes using cutting drills, often integrated into multi-purpose CNC machines for versatility.

Perfecting Surface Finish: Techniques for Excellence

Attaining flawless surface finishes demands attention to detail and adherence to best practices:

Tool Selection: Opt for cutting tools with simple geometries to ensure optimal results.

Feed Rate Optimization: Maintain recommended feed rates to prevent surface imperfections.

Effective Clamping: Secure plastic materials properly to minimize vibrations and ensure a pristine finish.

Cutting Speed Calibration: Adjust cutting speeds within recommended ranges for each plastic type to achieve desired results.

Advantages of CNC Plastic Machining

In a landscape dominated by injection molding and 3D printing, CNC plastic machining offers distinct advantages:

Precision and Accuracy: CNC machining delivers unparalleled precision, ensuring consistency across products.

Complex Designs: Capable of handling intricate geometries with finesse, CNC machining facilitates the creation of complex components.

Tight Tolerance: With high accuracy and precision, CNC machining achieves tight tolerances critical for many applications.

Material Versatility: CNC machining accommodates a wide array of plastics, providing flexibility without compromising quality.

Common Applications of CNC Plastic Parts

From medical devices to automotive components, CNC plastic parts find diverse applications:

Medical Equipment: Precision-machined plastic parts play a pivotal role in various medical devices and implants.

Food and Beverage Industry: Hygiene and precision are paramount in food-grade applications, driving the demand for CNC plastic parts.

Electrical Insulation: Plastic components serve as reliable insulators in electrical devices, ensuring safety and performance.

Automotive and Aerospace: CNC precision enhances the reliability and efficiency of plastic components in vehicles and aircraft.

Optical Industry: Plastics like acrylic are prized for their optical clarity, making them indispensable in lens manufacturing.

Mastering CNC plastic machining demands a nuanced understanding of material properties, machining techniques, and surface finishing methods. By harnessing the precision and versatility of CNC technology, manufacturers can create durable, high-quality plastic components tailored to diverse industrial and consumer needs.

CNC-Machining

Find various CNC-Machining products from our factory, and get the free OEM/ODM services.