- 0086 189 2383 9762

- [email protected]

- 268 Shu'an Rd, Dongguan, Guangdong Province, China, 523850

- Home

- CNC Machining

- Pages

- CNC Brass Parts Machining Service Manufacturing Custom

CNC Brass Parts Machining Service Manufacturing Custom

Understanding CNC Machining of Brass Parts

CNC Brass Parts machining of parts involves a nuanced approach, particularly when working with different metals or alloys. Brass, while highly machinable, presents unique characteristics and considerations that distinguish it from other materials. Exploring the intricacies of machining brass can aid in determining its suitability for your project.

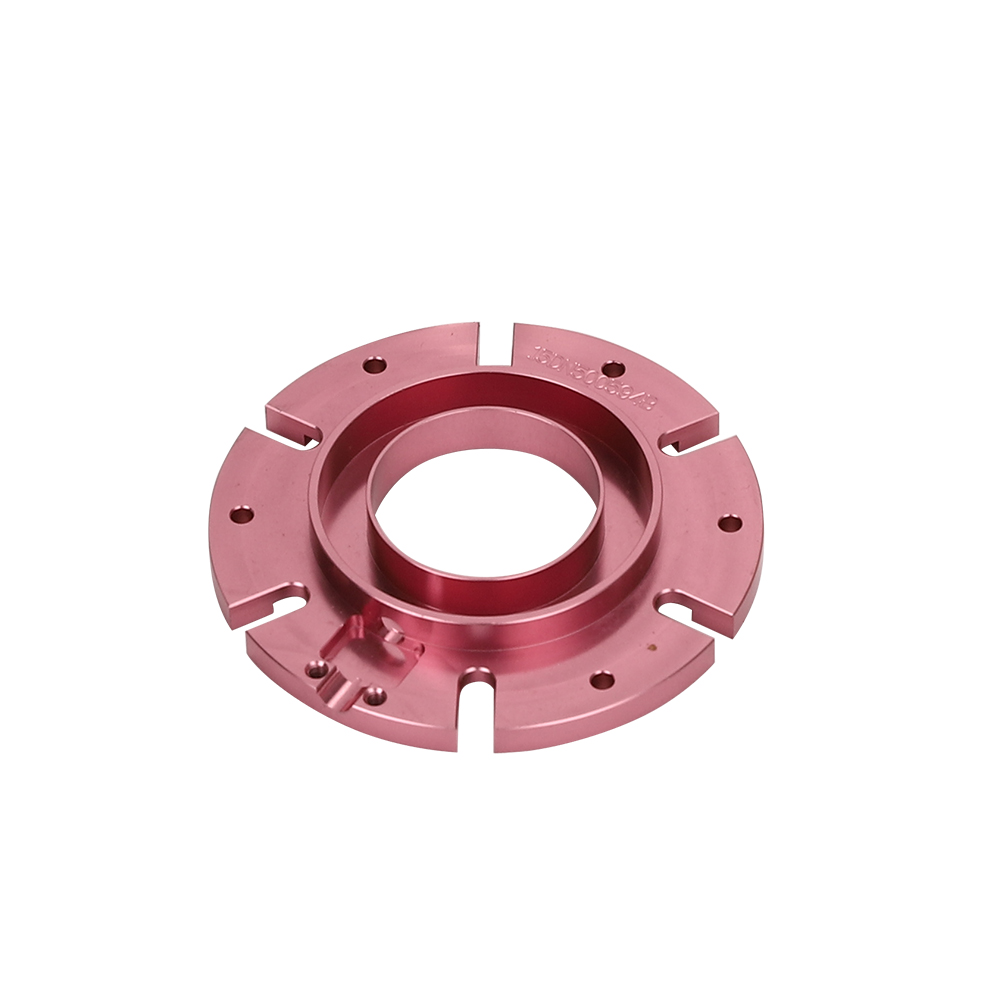

Common Brass Parts and Applications

CNC Brass Parts finds extensive use across various industries, contributing to the manufacturing of valves, nozzles, bearings, knobs, hinges, fluid fittings, plumbing components, electronic parts, and certain medical devices. While brass offers versatility, its composition may not align with every application’s requirements, necessitating a careful evaluation of its suitability.

Determining Brass Suitability for Your Project

Assessing whether brass aligns with your project involves weighing factors like machinability, durability, corrosion resistance, and thermal properties. Understanding these aspects enables informed decision-making regarding material selection. While brass offers several advantages, it’s essential to consider both its benefits and limitations in the context of your project’s specific needs.

Benefits of CNC Brass Parts

Brass, comprising copper and zinc with potential additives like silicon, tin, lead, aluminum, or iron, boasts notable advantages. These include excellent machinability, corrosion resistance, diverse finishing options, durability, precise tolerances, and effective sealing capabilities. Leveraging these benefits enhances the performance and longevity of CNC machined brass parts.

The exceptional machinability of brass stems from its composition and mechanical properties. With high ductility, flexibility, and a favorable friction coefficient, brass allows for efficient machining operations, enabling high feed rates and minimal coolant requirements. This ease of machining extends to various CNC machining techniques, ensuring the production of quality components with precise dimensions and superior surface finishes.

Challenges Associated with CNC Brass Parts Usage

Despite its merits, brass presents certain drawbacks that may render it unsuitable for particular applications. Factors such as toxicity (due to lead content), comparatively lower strength, susceptibility to corrosion in harsh environments, higher cost compared to alternatives like steel or aluminum, and aesthetic concerns related to tarnishing must be carefully considered before opting for brass parts.

Exploring Brass Grades for CNC Machining

Different brass grades offer distinct characteristics tailored to specific applications. Variants like C360 (Free Machining Brass), C230 (Red Brass or Nordic Brass), and C464 (Naval Brass) possess unique compositions and properties, catering to diverse machining needs. Understanding these grades empowers decision-making regarding material selection based on project requirements.

CNC machining of brass involves subtractive manufacturing techniques utilizing advanced CNC machine tools equipped with carbide inserts and computerized controls. These tools meticulously remove layers of material from brass workpieces, guided by programmed instructions to achieve the desired shapes and dimensions. The process relies on spindle speed control to optimize material removal rates, ensuring accuracy and consistency in component fabrication.

Making an Informed Decision

With a comprehensive understanding of brass types, their advantages, disadvantages, and available options, you can confidently determine whether brass is the optimal material for your project. While CNC machined brass parts serve various applications, aligning the material choice with your project’s specific demands ensures optimal performance and longevity. For expert guidance or assistance with CNC machining services, don’t hesitate to reach out for personalized support.

Understanding CNC Brass Parts and Its Properties

Brass, an alloy composed of copper and zinc, offers a unique blend of mechanical properties, making it a highly sought-after material across various industries. Its corrosion resistance, durability, and low friction coefficient make it an ideal choice for numerous applications, ranging from electrical to plumbing and medical fields. The distinctive characteristics of brass render it conducive to CNC machining processes, facilitating the production of intricate and precise components.

The composition of brass alloys plays a crucial role in determining their machinability and overall performance during CNC machining. While the primary constituents are copper and zinc, additional elements like tin, lead, chromium, or magnesium may be incorporated to enhance specific properties based on application requirements. The presence of lead and copper significantly enhances machinability, facilitating seamless fabrication processes with CNC brass machines.

Mechanical Properties of CNC Brass Parts

Brass exhibits a diverse range of mechanical properties that contribute to its suitability for CNC machining applications. Notable characteristics include a low coefficient of friction, robust wear resistance, high corrosion resistance, ductility, and malleability. These properties ensure that machined brass components not only meet stringent dimensional tolerances but also withstand diverse environmental conditions and mechanical stresses.

In conclusion, CNC machining of brass offers a versatile and efficient manufacturing solution for producing precision components across various industries. The inherent properties of brass, coupled with advanced CNC machining techniques, enable the fabrication of complex parts with exceptional accuracy and surface finishes. By understanding the composition and mechanical behavior of brass alloys, manufacturers can optimize machining processes to meet the specific requirements of diverse applications, ensuring the delivery of high-quality brass components tailored to individual needs.

CNC-Machining

Find various CNC-Machining products from our factory, and get the free OEM/ODM services.