- 0086 189 2383 9762

- [email protected]

- 268 Shu'an Rd, Dongguan, Guangdong Province, China, 523850

- Home

- CNC Machining

- Pages

- High Quality Metal Fabrication Custom Stainless Steel Parts

High Quality Metal Fabrication Custom Stainless Steel Parts

Understanding Metal Fabricating

Metal fabrication is the process of crafting products or structures by manipulating metal through cutting, bending, and assembling. It’s a value-added process that transforms raw metal materials into finished goods, essential for various industries and applications.

The Three Phases of Metal Fabricating

Metal fabrication typically involves three phases: design, fabrication, and installation. Design encompasses creating shop drawings to precise measurements, fabrication involves cutting, bending, and assembling metal, while installation is the final stage where the end product or structure is put together.

Diverse Raw Materials

Metal fabricators work with a range of raw materials, including plate metal, expanded metal, welding wires and rods, and cast metal. This diversity enables them to produce a wide array of finished metal parts or structures tailored to specific requirements.

Types of Metal Fabricating

Metal fabricating is segmented into various types, with three of the most common being industrial, structural, and commercial fabrication. Each type serves distinct purposes and industries.

Industrial Metal Fabrication

Industrial metal fabrication integrates parts or assemblies into large-scale industrial products. Industries such as aerospace, automotive, and material handling rely on industrial fabricators to produce components like tanks, silos, and heavy machine parts.

Structural Metal Fabricating

Structural metal fabricating involves creating high-strength metal parts for construction projects. Steel, with its excellent strength-to-weight ratio, is commonly used in structural applications, including the construction of buildings, bridges, and towers.

Commercial Metal Fabricating

Commercial metal fabrications produces parts for commercial venues like restaurants, stores, and public spaces. Products such as guardrails, awnings, shelving, and sinks are fabricated to meet functional and aesthetic requirements.

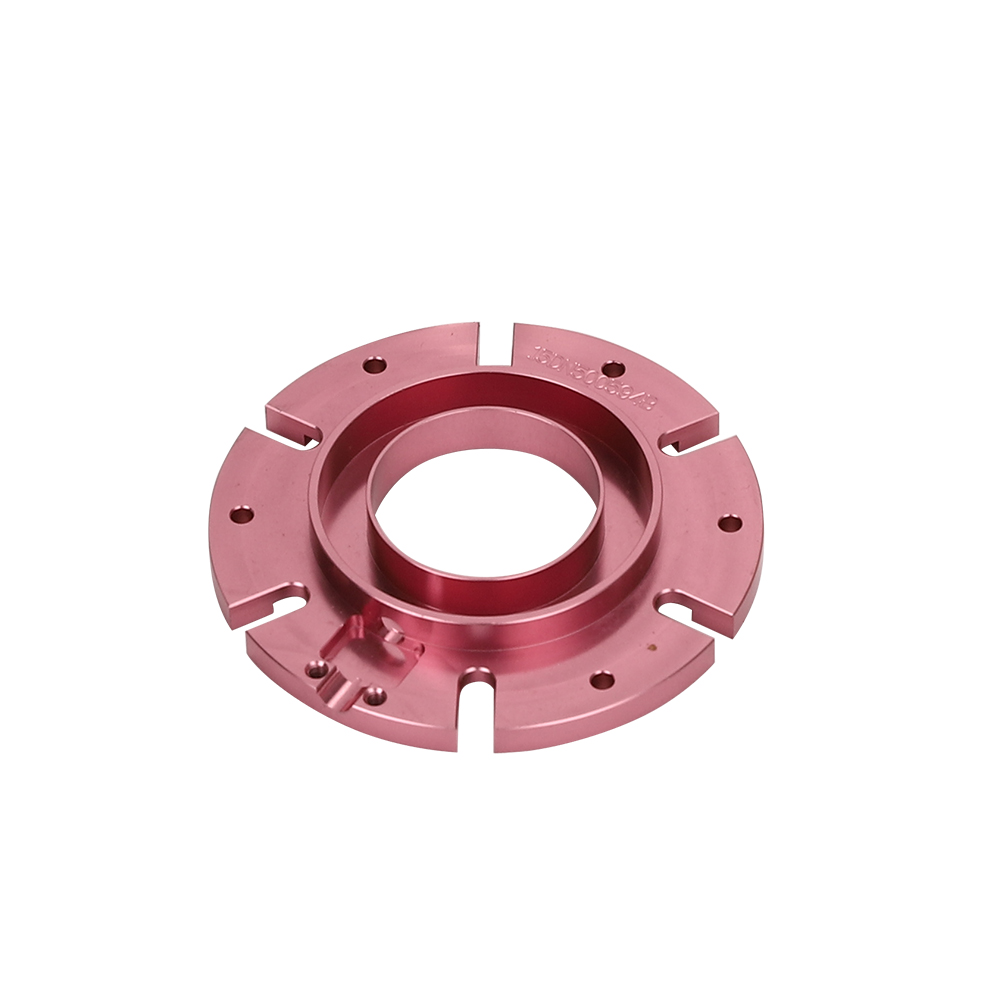

Custom Metal Fabrication

Custom metal fabricating encompasses all types and involves creating unique parts tailored to specific customer needs. It’s a versatile process that utilizes cutting-edge techniques to produce precise and high-quality metal components.

The Fabrication Process

Metal fabricating begins with sheet metal, typically no thicker than a quarter inch, which is then shaped using various techniques like cutting, stamping, shaping, folding, and welding. Custom fabrication involves creating new, unique parts through creative combinations of these processes.

Design and Collaboration

In the design stage, CAD software is often used to create precise designs, with input from both the customer and the fabricator. Steel detailing, or the process of modifying designs for fabrication, ensures that the final product meets both design specifications and fabrication requirements.

Metal fabrication is a versatile and essential process that underpins various industries and applications. Whether it’s crafting industrial machinery, constructing buildings, or enhancing commercial spaces, metal fabrication plays a vital role in bringing ideas to life.

CNC-Machining

Find various CNC-Machining products from our factory, and get the free OEM/ODM services.