- 0086 189 2383 9762

- [email protected]

- 268 Shu'an Rd, Dongguan, Guangdong Province, China, 523850

- Home

- CNC Machining

- Pages

- Custom CNC Metal Machining Metal Fabrication Metal Parts

Custom CNC Metal Machining Metal Fabrication Metal Parts

Introduction: Evolution of Custom Metal Parts Fabrication

Custom CNC Metal Machining fabrication has undergone significant evolution over the past few decades, driven by advancements in technology and the introduction of newer machines capable of precision measurements and cutting. This article explores the intricacies of factory CNC laser cutting for custom metal parts fabrication, offering insights into the processes, materials, and industries involved.

From Concept to Creation: Bringing Designs to Life

Clients approach metal fabrication companies with a myriad of requirements, from simple sketches to precise measurements or existing physical parts. Regardless of the starting point, the goal is to translate these concepts into tangible products. Expert teams collaborate with clients, providing design recommendations and ensuring the integrity of the final product.

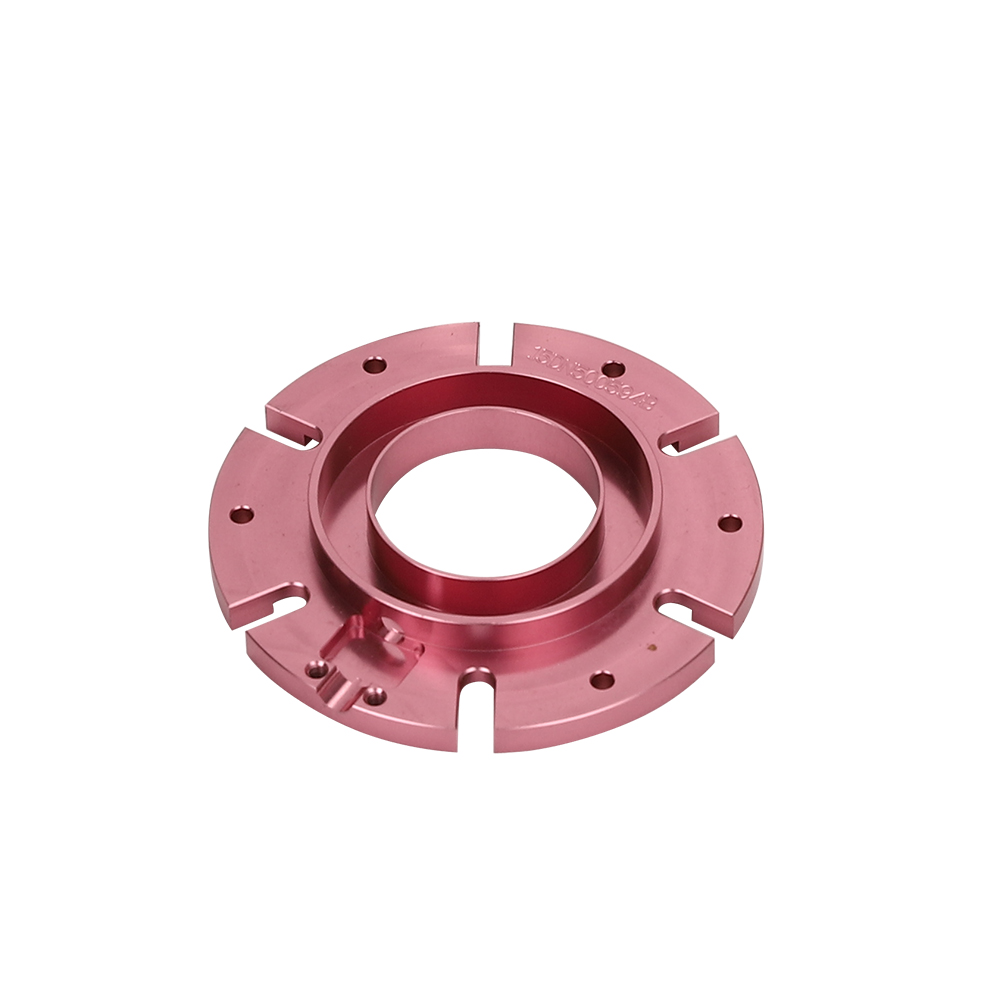

Custom CNC Metal Machining fabrication encompasses various processes, including precision stamping, die cutting, CNC machining, and OEM replacement. Each method caters to specific needs, offering solutions for a wide range of applications. Whether it’s forming intricate shapes or replicating OEM parts, the services provided ensure reliability and cost-effectiveness.

Selecting the appropriate metal material is crucial in metal fabrication. Options like aluminum, brass, copper, titanium, and stainless steel offer distinct properties suited to different requirements. From lightweight durability to exceptional corrosion resistance, understanding the characteristics of each material guides the fabrication process.

Exploring Manufacturing Methods: From CNC to Metal 3D Printing

Custom CNC Metal Machining fabrication involves a spectrum of manufacturing methods, each with its strengths and applications. From CNC milling and turning to extrusion, metal casting, and metal injection molding, understanding these techniques is essential for choosing the most suitable approach. Let’s delve into eight key manufacturing processes:

CNC Milling and Turning: Precision in Motion

CNC milling and turning represent core machining technologies, offering automated solutions for precise metal shaping. By leveraging computer-controlled movements, these processes produce reliable components with tight tolerances. Suitable for various materials, CNC machining serves diverse industries, including aerospace, automotive, and consumer products.

Extrusion: Shaping Possibilities

Extrusion is a versatile method for creating complex metal profiles with consistent cross-sections. By pushing heated metal or plastic through a die, manufacturers form intricate shapes with minimal material waste. Widely used in industries like construction and automotive, extrusion enables the production of diverse components with ease.

Metal Casting: Tradition Meets Innovation

Custom CNC Metal Machining casting remains a cornerstone of manufacturing, offering a time-tested approach to shaping metal parts. By pouring liquid metal into molds, manufacturers create components with precision and efficiency. From sand casting to investment casting, this method caters to various industries, including automotive and plumbing.

Die Casting: Precision at Scale

Die casting excels in producing high volumes of intricate metal parts with exceptional accuracy. Utilizing steel molds and low-melting-point metals, this process delivers reliable components for critical applications. With applications in aerospace, automotive, and consumer electronics, die casting combines efficiency with performance.

Metal Injection Molding: Precision in Small Packages

Custom CNC Metal Machining injection molding offers a cost-effective solution for creating small, intricate metal parts with high precision. By blending metal powders with polymers, manufacturers produce components ideal for applications requiring intricate details. From medical devices to aerospace components, metal injection molding caters to diverse industries with its versatility.

Forging: Strength Through Force

Forging harnesses the power of heat and pressure to shape metals into robust components. By manipulating the material’s grain structure, manufacturers create parts with superior strength and durability. From automotive components to industrial tools, forging plays a vital role in producing high-performance metal parts.

Sheet Metal and Stamping: Efficiency in Forming

Sheet metal fabrication offers a rapid and cost-effective method for creating structural components from metal sheets. Through stamping and bending processes, manufacturers shape flat sheets into three-dimensional structures. Widely used in industries such as electronics and robotics, sheet metal fabrication delivers efficient solutions for various applications.

Metal 3D Printing: Innovating Complexity

Metal 3D printing revolutionizes metal fabrication by enabling the production of intricate geometries with unmatched precision. By layering metal powders or wire, additive manufacturing techniques create complex parts with minimal material waste. From aerospace to medical devices, metal 3D printing pushes the boundaries of design and manufacturing.

As technology continues to evolve, so too does the field of metal fabrication. By leveraging a diverse range of manufacturing methods and materials, manufacturers can meet the demands of increasingly complex applications. From CNC precision to additive innovation, metal fabrication remains at the forefront of modern manufacturing, shaping industries and driving innovation forward.

CNC-Machining

Find various CNC-Machining products from our factory, and get the free OEM/ODM services.