- 0086 189 2383 9762

- [email protected]

- 268 Shu'an Rd, Dongguan, Guangdong Province, China, 523850

- Home

- CNC Machining

- Pages

- Custom CNC Machining Stainless Steel CNC Machining Services

Custom CNC Machining Stainless Steel CNC Machining Services

Stainless Steel CNC Machining Services

Stainless steel alloys boast exceptional mechanical properties, showcasing high tensile strength, ductility, wear resistance, and corrosion resistance even under elevated temperatures.

Expert CNC Stainless Steel Machining Service

CNC-Machining emerges as the premier choice for reliable and efficient stainless steel components. Our ISO 9001-certified facility offers state-of-the-art precision, accommodating custom designs from rapid prototyping to high-volume production. Expect quick turnarounds in a dependable environment every time!

Our specialized team delivers unparalleled CNC machining services, encompassing milling, turning, and lathe work. Tailored pricing based on project stages ensures maximum value with unbeatable delivery timeframes. Count on our dedicated experts for bespoke support to achieve all project goals.

About The Material

Stainless steel stands out as an ideal material for CNC machining, boasting excellent workability and remarkable uniformity. Its corrosion resistance, wear resistance, and high tensile strength make it a top choice for industrial applications seeking enduring quality components. With great ductility and formability, stainless steel meets project parameters effortlessly, making it a sought-after material for precision machinery like CNCs.

Key Features:

- Corrosion resistance

- Strength

- Versatility

- Surface

- Durability

Stainless Steel Alloys For Custom CNC Machining

Stainless steel CNC machining leverages computer numerical control (CNC) machines to shape and cut stainless steel into precise and intricate parts or products. With a diverse selection of stainless steel variations, including 304/304L, 316/316L, 303, or Type 360 (17-4), we ensure high-quality performance meeting any specifications or requirements.

Custom CNC Machining Stainless Steel Applications

Industries spanning medicine, robotics, and aerospace rely on CNC machining of stainless steel for high-strength parts. This robust material finds application in environments requiring reliable durability or extreme temperature operation, making it the ideal solution where reliability is paramount.

Surface Finishes For Custom CNC Machining Stainless Steel Parts

CNC-Machining offers a range of surface finishes for CNC-machined stainless steel parts, including powder coating, bead blasting, and plating. Each finish offers distinct advantages, ensuring your requirements are met with precision.

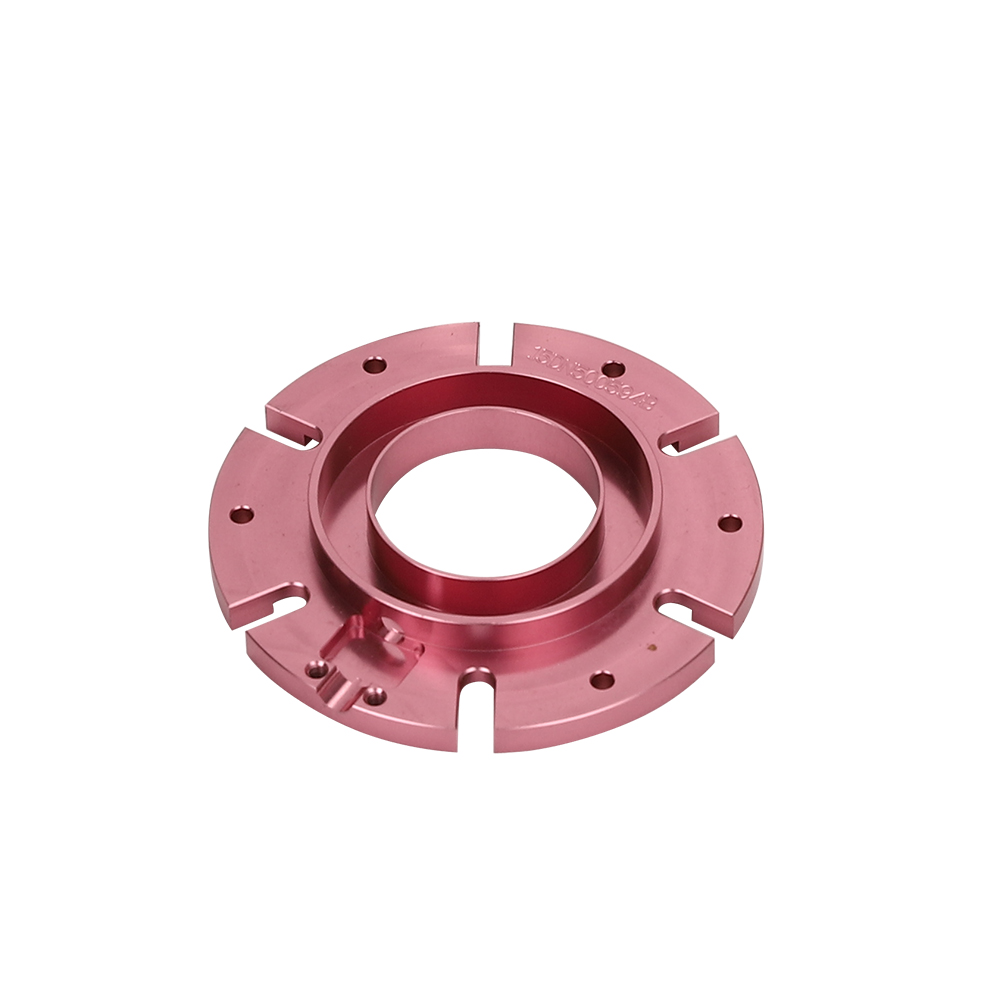

Gallery Of Custom CNC Machining Stainless Steel Parts

Benefit from our superior manufacturing capabilities, catering to customers across various industries. From medical devices and aerospace technology to hardware startups and marine robotics, CNC-Machining handles projects of all sizes with expertise and finesse.

In summary, stainless steel proves to be an incredibly versatile material for CNC machining, providing a wide array of alloys customized to meet specific needs across various industries. Whether it’s for industrial machinery, automotive components, or precision instruments, selecting the appropriate stainless steel grade can greatly improve the performance and durability of your CNC machined parts.

CNC-Machining

Find various CNC-Machining products from our factory, and get the free OEM/ODM services.